Introduction: A Wake-Up Call

Imagine discovering a faulty component in a medical device only after receiving customer complaints—six months late. This nightmare scenario recently became reality for a manufacturer. It highlights why robust traceability and warranty management aren’t just regulatory boxes to check. They are critical business imperatives.

In the highly regulated medical device industry, FDA guidelines such as 21 CFR Part 821 and Part 810 govern operations. Global standards like ISO 13485 and EU MDR also dominate these operations. Every component must be traceable from procurement through production. It must continue through distribution and ultimately reach the patient. This requirement goes beyond compliance – it’s a foundational pillar of patient safety and corporate integrity.

Oracle Fusion Cloud SCM solutions address these challenges directly. They provide a cohesive ecosystem to ensure real-time visibility. The solutions also offer precise recall management and streamlined warranty handling.

Product Genealogy: Tracing from Components to Patients

Imagine a patient with a Class III implantable device. Should a single component within the device fail, precise traceability isn’t just a regulatory mandate; it’s potentially life-saving. Oracle Fusion Cloud enables this precision by:

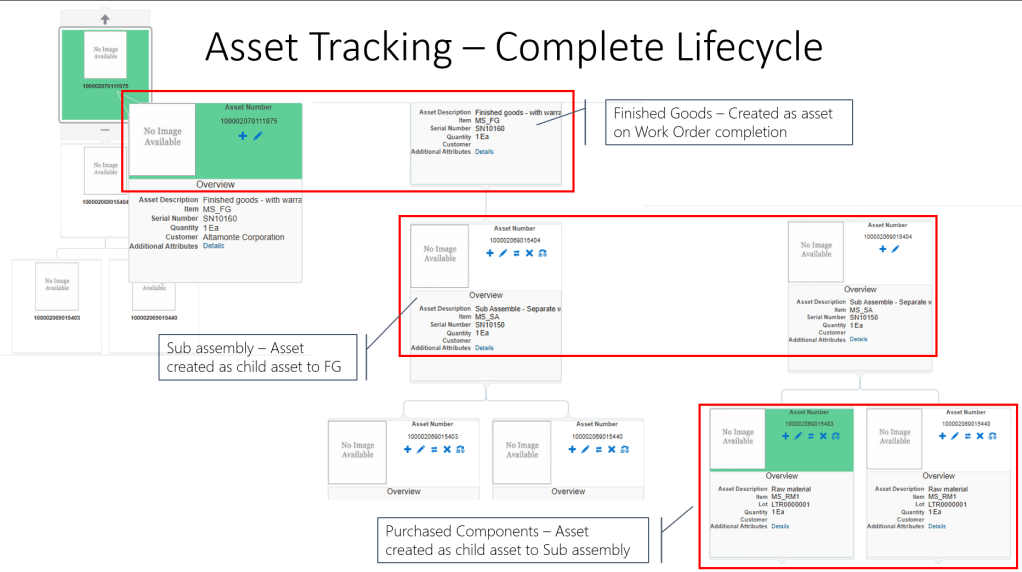

- Serialized Manufacturing: Unique identifiers (UIDs) can be assigned and tracked at every step—from components and sub-assemblies to finished goods. Serialized manufacturing refers to where a serial number is allocated to the work order up front and all the operations are carried out at an individual serial number level

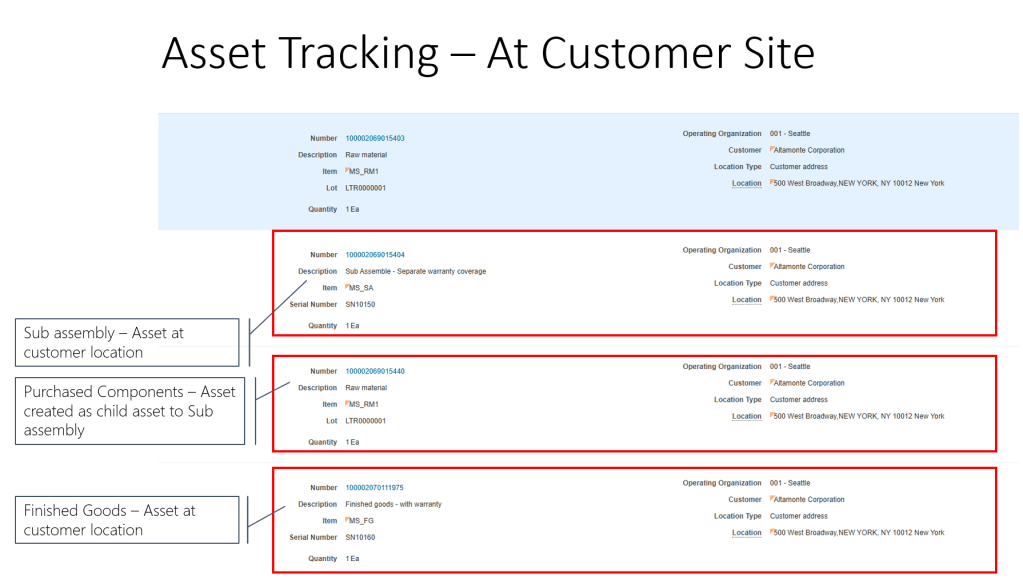

- Full Life cycle Asset Tracking: Devices are tracked from procurement through manufacturing and distribution to patient use. This tracking is essential for quick response in recalls or complaints.

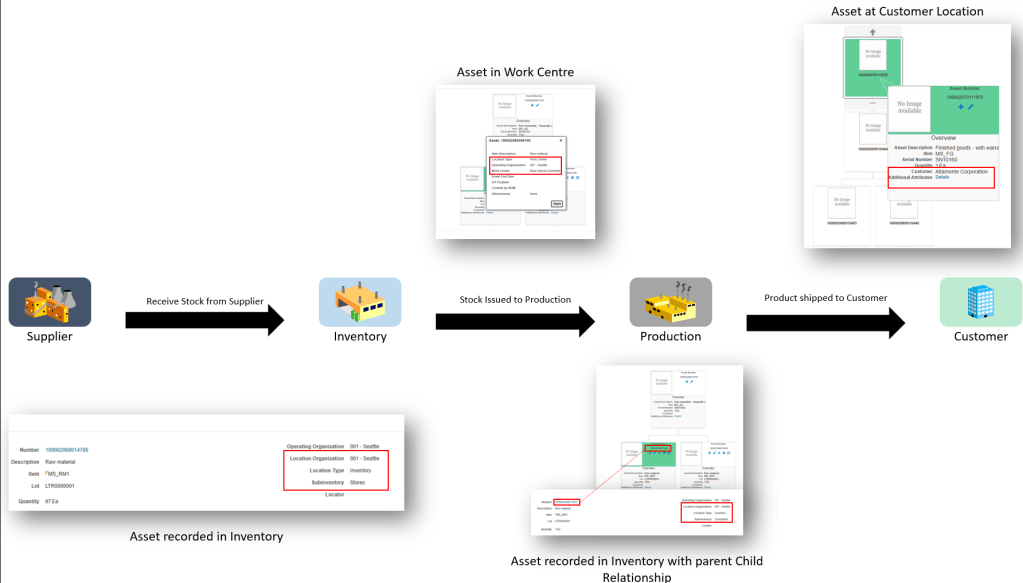

Process Overview

- Components are assigned unique asset numbers during procurement. These can be an individual serial number or a lot number

- During the production process, Sub-assemblies and finished goods capture these numbers as a part of the manufacturing operations.

- Oracle’s centralized Install Base maintains the genealogy from raw material to final device.

Oracle AI agents can play a critical role here across various functions

- Proactively identify anomalies in component usage or supplier specification changes – Agents can analyse vendor provided quality results as a part of the ASNs and validate for anomalies. They can further recommend holds on lots and serials imapcted by this analysis. This approach significantly reduces the risk of faulty products reaching the market.

- Enable natural language search capabilities– Agents can help look through asset hierarchy and help customer service reps during customer inquires

- Product Recall – AI agents can action product recall notices or customer feedback or QA disposition process to quarantine lots or initiate product recalls from customers

Complex Warranty Management: Beyond Simple Guarantees

Warranty management in medical devices isn’t straightforward. Consider a scenario where a medical ventilator has a standard five-year warranty, yet its internal motor component carries a seven-year warranty. Further complexity arises with consumable components like masks, requiring annual replacements within warranty periods.

Oracle Fusion Cloud simplifies these complexities by:

- Flexible Warranty Definitions: Allows distinct warranty duration for finished goods and individual components.

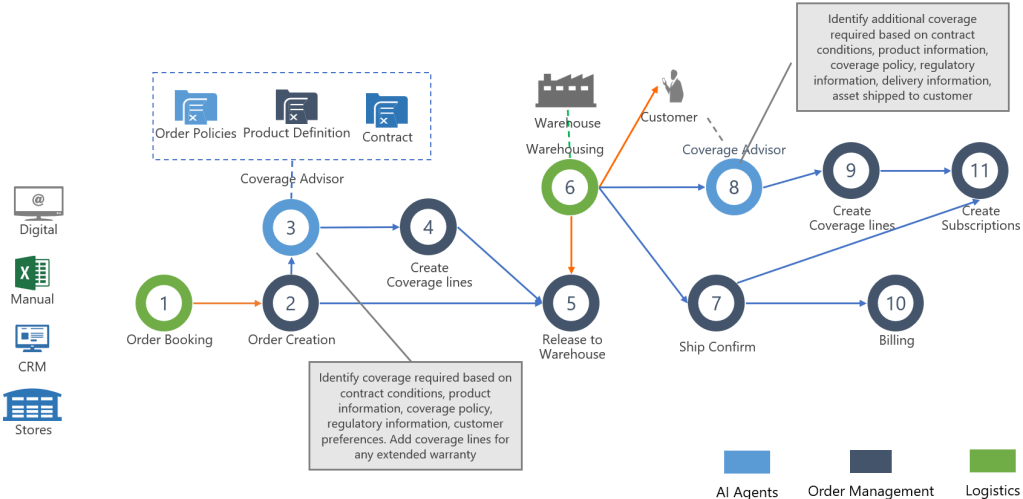

- Automated Warranty Assignment: Orders automatically create appropriate warranty subscriptions, linking coverage directly to shipped assets.

Consider another example—a medical device bundled with consumables like masks or pads. These consumables must meet medical compliance standards and require mandatory periodic replacement within the warranty period. Oracle enables tracking these components as assets. It allows the creation of coverage contacts with entitlements. This supports automatic replenishment and ensures compliance and uninterrupted patient care.

Real-world Example: A ventilator’s motor fails within its seven-year extended warranty. Oracle Cloud quickly identifies the warranty coverage, automates replacement fulfillment, and handles financial accounting seamlessly.

Oracle AI agents further streamline warranty handling. They interpret contracts, sales orders, and regulatory documents. This allows them to dynamically assign extended warranties. They also manage special coverage scenarios automatically.

Efficient Recall Management: Respond Rapidly and Precisely

Effective recalls hinge on accurate, real-time information. Oracle Product Recall Management uses detailed traceability data. This enables rapid identification of affected products down to individual serial or lot numbers. Imagine receiving an FDA recall notice about a specific batch of batteries. Oracle swiftly identifies every affected device and customer, automates recall communications, and manages the reverse logistics seamlessly.

Oracle’s AI capabilities enhance recall effectiveness by:

- Automatically detecting production anomalies to preempt recalls.

- Cross-checking supplier notifications against production records.

- Accelerating response times and reducing manual errors.

Exploring Further Possibilities

We’ve only scratched the surface. Delving deeper, Oracle Fusion Cloud supports comprehensive warranty subscriptions that enable efficient returns, replacements, and repairs.

This capability extends naturally into rental scenarios, allowing periodic billing for shipped assets.

Similar to warranty Oracle cloud allows for rentals to be defined as coverage based on the scenarios and circumstances this can be a monthly billing cycle, one time payment or at no charge (for temporary rentals)

The asset tracking allows to track assets at customer location and the rental contracts can be tracked for expiry. The contract can be enabled for manual or automatic renewal on expiry and additional entitlements like free returns, replacements and upgrades can be included

Integrating these functionalities can significantly streamline recall processes.

AI further enhances these scenarios, whether it’s identifying non-conformance during manufacturing, reviewing quality data, interpreting documentation to suggest warranty inclusions,

AI provides opportunities to allow your call centers and service teams. They can swiftly access product details. Install base information and genealogy can also be accessed for customer support.

AI agents can further leverage your company policy, product information, and end of life information. They use contract details to assess upgrades and returns (if the unit is now end of life). They can start the process automatically. Regular service inspections, check in or maintenance activities can also be managed to move you from a reactive Request to Resolve model to a proactive Sense to Resolve model

Going beyond compliance, this can be a big game changer in driving revenue opportunities. The install base data in the system lets you assess the existing install base and recommend upgrades to your customers, recommend part replacements, up-sell services and also analyze trends in customer usage

Conclusion: Building Confidence Through Visibility and Automation

Oracle Fusion Cloud offers medical device manufacturers a powerful way to transform regulatory burdens into strategic advantages. The platform delivers precise product genealogy tracking. It provides sophisticated warranty management. It also offers responsive recall capabilities, all enhanced by integrated AI. These features ensure compliance. They boost operational efficiency. Most importantly, they protect patient safety.

Would love to hear from you—what unique scenarios or challenges have you encountered in traceability or warranty management? How is your organization approaching these complexities?